Analysts: Industry must master core tech in key sectors

Manufacturers should make more of an effort to master core technologies in key sectors and improve their R&D capabilities-while introducing advanced technologies and equipment from abroad-analysts said on Thursday, in response to Premier Li Keqiang's comments this week on the Made in China 2025 initiative.

"On the one hand, Chinese enterprises should make more of an effort to strengthen corporate management and enhance the quality of their products as well as recruiting more R&D expertise, in order to enhance their competitiveness," said Luo Zhongwei, a researcher at the Institute of Industrial Economics under the Chinese Academy of Social Sciences.

On the other hand, they needed to learn and absorb experience and expertise from their foreign counterparts to bridge the quality gap between products from home and abroad, Luo said.

He added that against the backdrop of globalization, moves to open up, share and integrate among companies should be the trend going forward.

Premier Li reiterated on Wednesday that being an important part of the supply-side structural reform, the Made in China 2025 initiative is supposed to further enhance product quality and better meet consumers' demands.

But the initiative will never lead to reducing imports and retreating from further opening-up, he said, stressing that Chinese enterprises should nurture their spirit of craftsmanship and let their products win the trust of consumers.

"We should master core technologies in some key strategic areas, as well as introducing advanced technologies from abroad," Luo said.

"Globalization has become an irresistible trend and we should make full use of it as China has been a beneficiary of it over the past few decades."

The Made in China 2025 initiative, which is designed to upgrade China's manufacturing capability, set a target that more than 40 percent of key equipment components and key infrastructure material will be China-made by 2020, with an increase to 70 percent by 2025.

"With the ever-increasing demands from domestic consumers, enterprises have to produce high-quality products to satisfy their demands," said Qu Xianming, an analyst from the Chinese Machinery Industry Federation.

"We have some advantages in telecommunications, electric power and rail transit equipment and we are able to export these products and technologies. However, we still have to import chip manufacturing equipment, aero-generators and medical equipment from other countries," Qu said.

He added that in those areas Chinese firms were lagging behind, but they were also closing the gap with their overseas counterparts.

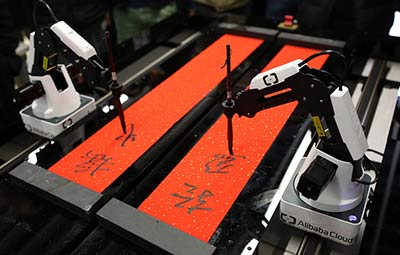

Gree Electric Appliances Inc, a leading Chinese home appliance maker, said it had made progress in intelligent manufacturing by using industrial robots in a variety of production cycles.

"Most of the robots are assembled with imported core components, but it is important that we develop our own technology and create our own brands," said Gree President Dong Mingzhu.